OMRS (Online Monitoring of Rolling Stock) initiative measures loads generated at wheel-rail interaction and generates alerts for unusual forces. It leads to identifying wheel flats, suspension defects, etc. Veneklasen’s OMRS solution is developed encompassing the functionality of Sound, Vibration, and Ultrasound into one system and using proprietary algorithms predicting defects at a very early stage than any other system.

Veneklasen – Railway Wear Tear Damage Prediction System of Rolling Stock will enable Predictive Maintenance of coaches, wagons, and locomotives by meeting the following functionalities:

We are improving reliability and safety by early warning of distress or impending failures in wheels and wheel bearings using the vibration signature of the sensors.

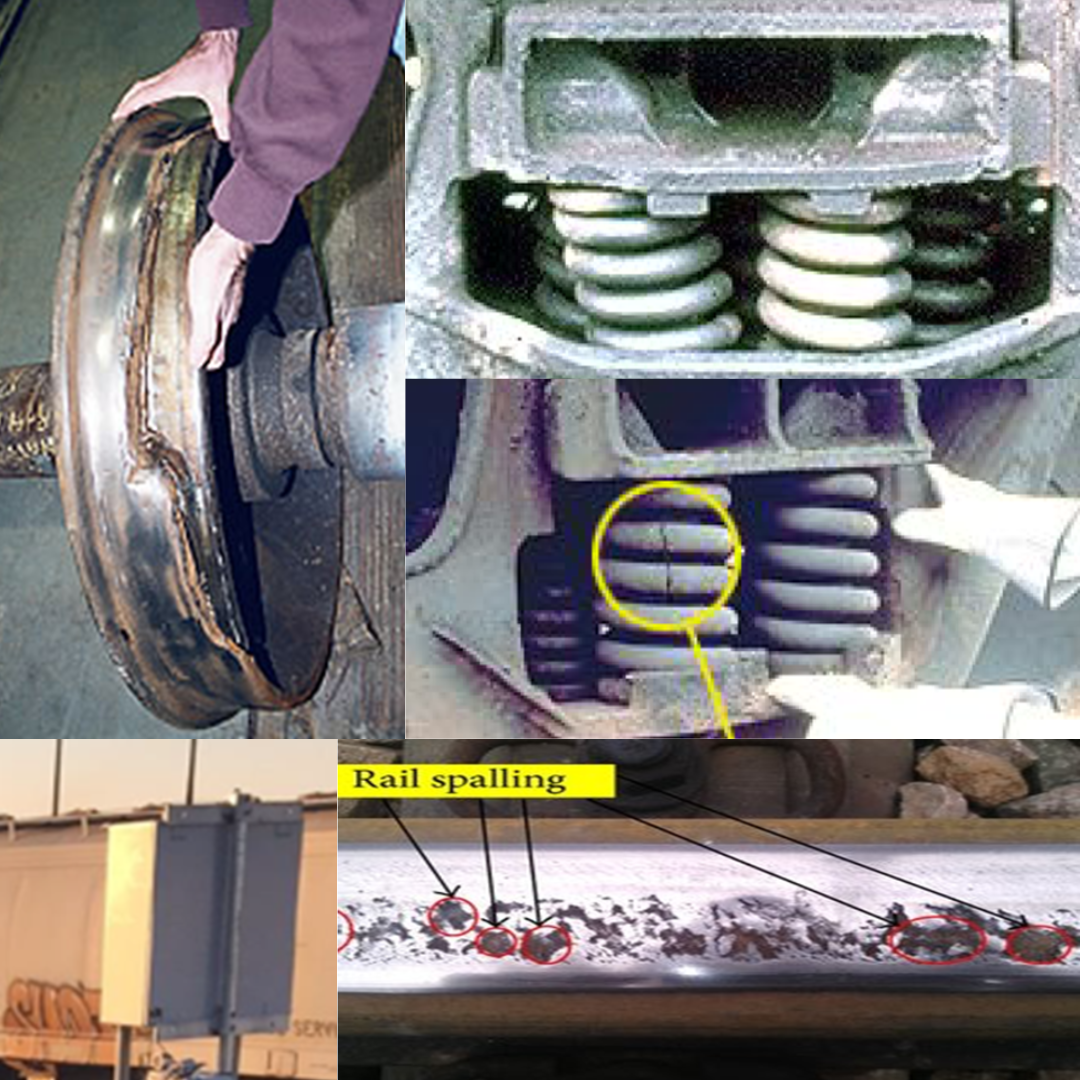

Improvement in the reliability of these assets by detecting early signs of deterioration in wheels, wheel bearings, broken wheels, wheel flat, spalling, hanging parts, missing springs, brakes, faulty air valves, etc. thus providing ample time for planning preventive and predictive maintenance and avoiding sudden breakdowns in service.

It enables scientific decision-making for the maintenance of assets based on accurate deterioration trending and quantified indices of the state of health of these assets to plan condition-based maintenance rather than time-based maintenance.

Ours is an Easy Rail Predictive Maintenance Monitoring System operation by simple, automatically generated, and actionable alerts.